Growing fresh tomatoes in the basement year-round? Awesome! The electric bill, however, was scary. The solution? Off-grid aquaponics with its own power plant. While it’s possible to generate energy from organic waste to power an aquaponic system in your basement, that’s not what this married couple decided to do.

While kicking around ideas to make their personal indoor food production cost-efficient, it dawned on them that they weren’t alone in this dilemma. It isn’t just home growers that need a way to escape the cost of powering their indoor garden, but farmers in many climates are in the same boat. The energy cost is why most indoor farms produce only fast crops like greens and herbs. Even if only using LEDs, the high cost of electricity is certainly not making the price of fresh, locally grown food more affordable. Adding fish does reduce the cost of inputs while increasing your harvest. But what about efficiently growing fruiting crops?

With the right grow lights, it is possible to grow fantastic-tasting, garden-fresh tomatoes out of season in aquaponics. But using utility company energy makes the cost per pound astronomical! The only way to make them affordable for home consumption or the retail market is off-grid aquaponics. You could do the same thing with hydroponics, but the plant nutrients are inputs not generated by the system. No matter how you approach indoor growing, energy is a huge roadblock to productivity.

So, why not create a fully self-sustaining system that anyone could use? Once you’re not dependent on the grid for power, you can grow high-quality, all-natural, pesticide-free food cheaply anywhere. And AquaGrow Technologies was born. A company founded by scientists at the Illinois Institute of Technology, chemistry professor Elena Timofeeva, and physics researcher John Katsoudas.

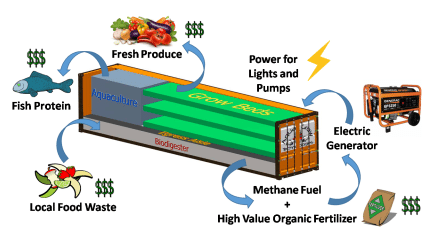

It didn’t happen overnight. They started playing around with aquaponics at home about 5 years ago but recently put together a viable approach to affordable growing that is highly sustainable in any location. Their off-grid aquaponics system design generates electricity by turning food waste into biogas via a methane digester. No, it’s not breaking technology, but housing the power plant, fish, and crops inside a single freight container is unique. And it’s got an added value manufacturing system as a bonus.

The biodigester creates 110 MWh of energy and high-quality organic fertilizer by eliminating 155 tons of food waste and 40 tons of CO2 from landfills annually. While the aquaponics system generates its own plant nutrients, the fertilizer byproduct is an easily marketable product in big demand. The methane fuels the generator, turning it into electricity to power grow lighting, pumps, etc.

Courtesy of AquaGrow Technologies

But how do you fit a biodigester big enough to fuel powerful grow lights and all the supporting system equipment? Timofeeva and Katsoudas enlisted the help of Nullam Consulting to come up with a flat digester that fits under the floor of the production area.

How productive is this off-grid aquaponics setup? They say that a single container unit can pay for itself in 2-3 years, generating $40,000-80,000 in profits annually. The units will sell for $150,000, but an investment that pays for itself in a reasonable time frame. Each unit can produce 14,500 pounds of produce and 1,100 pounds of fish a year. That’s in addition to the 45 tons of organic fertilizer the anaerobic digester generates annually from food waste. And it’s also possible to collect fees from grocery stores and food processing companies whose waste is being recycled.

Naturally, AquaGrow’s off-grid aquaponics system design isn’t without naysayers. There are always critics with skeptical views of anything new, so it’s not surprising to find soil-based agriculture scientists eager to envision flaws. Needless to say, its highly innovative approach to growing food in a mobile container has others who see its merits in the future of food. They’ve been chosen as a semi-finalist in the 2016 Cleantech Accelerator Open.

Timofeevan and Katsoudas are currently in the process of raising the funds to build their prototype. Their semi-finalist status in the Silicon Valley program adds a Cleantech advisor to their team to help develop their business strategy and market research. The 45-foot AquaGrow farm container will come to life within the next 18 months. The fully independent 45’x10’x10′ units are stackable and movable. Their easy-to-operate system includes advanced monitoring and controls for improved reliability and optimized efficiency and yields.

A very interesting development worth keeping an eye on as it comes together.

Learn More/Sources: